Plastic Injection Molded Housings / Enclosures

PMD has extensive experience designing injection molded electronics enclosures using Solidworks’ Advanced Surfacing modeling techniques.

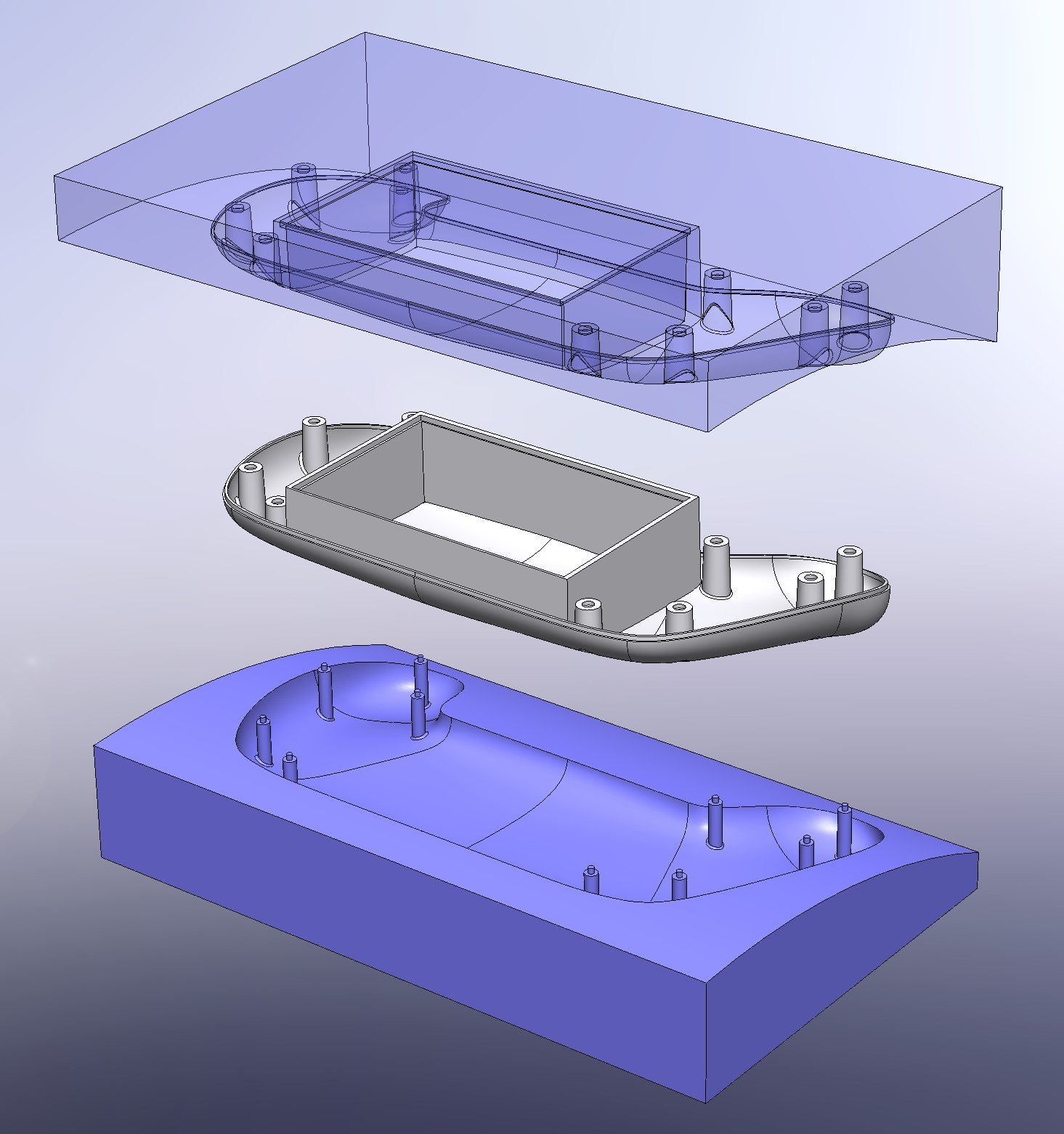

Achieving predictable results for complex molded components is achieved by creating cad models of the basic mold halves and inserts.

This “mock tooling” is used to communicate with the mold vendors to ensure the finished components reflect the design intent. (Nothing is left to "interpretation” by the mold vendor this way). All draft angles, fillet radii, etc. are included in the geometry. This level of attention to detail / “measure twice, cut once” approach is appreciated by the mold vendor as well as by the customer!

Several examples of Plastic Injection Molded Electronic Housings / Enclosures include the following:

Display / Camera Desktop Mounted Electronics Enclosure

Designed an enclosure as well as internal mounting components for a medical / physical therapy rehabilitation product.

Handheld Camera / Video Display Device for extreme high temperature environments.

Designed all mechanical components of a handheld camera / video display device with a form factor somewhat similar to a cordless drill, based upon the customer’s industrial design sketches. Worked with the customer to achieve the aesthetic design goals while making all of the components easily manufacturable. The design included required complexities such as overmolded grips, removable components, sealed internal cavities, etc.

Electronic Sensor Housings

Designed several sensor housings for humidity and temperature sensors which are used in relatively harsh environment applications (automotive, overseas shipping containers, etc.)